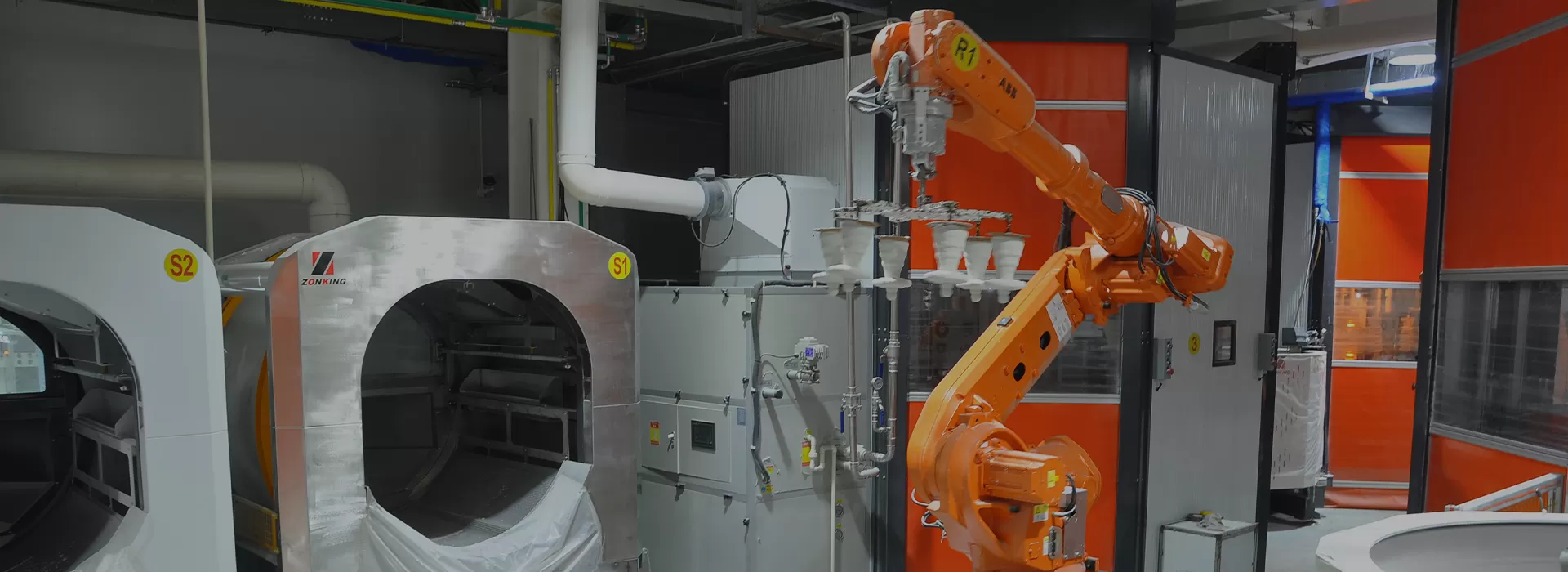

FULLY AUTOMATIC DIGITAL PRODUCTION LINE

Smart casting the future, one-click molding

Start Your Inquiry

We adopt invesment precision casting and a variety of machining technologies

We can provide our own heat treatment, surface treatment and a full range of inspection services to ensure product quality. These additional capabilities help us to provide a one-stop solution that allows us to guarantee competitive pricing, timely delivery and high quality.

Establishment

Plant area

Employees

Total assets of company

Annual output of precision casting

The world's top 500 enterprises cooperation

Full process chain database management system

Full process chain database management system Equipped with a multi-dimensional process database cluster, it achieves breakthrough unlimited product level compatibility and unlimited process formula management, perfectly adapting to the flexible production needs of multiple varieties and small batches.

Build a full-factor process database such as slurry rheological properties database, shell material performance database, and environmental parameter history database to achieve full-process traceability and intelligent retrieval of key parameters in the shell making process.

Smart production control platform

Smart production control platform Integrate intelligent scheduling engine and real-time production dashboard, and completely solve the process congestion problem through the dynamic optimization algorithm of the hanging chain, and realize independent process parameter configuration and precise drying time control of a single hanging point.

Support mixed-line production mode of multiple categories of products, equipped with ERP/MES standardized data interface to ensure seamless connection with enterprise-level management system.

Digital twin visualization system

Digital twin visualization system Based on three-dimensional virtual mapping technology, the production line digital twin is constructed. Operators can monitor the equipment operation status and process execution progress in real time through the interactive interface, and achieve intelligent operation and maintenance of "remote perspective and full control".

Innovative drying technology system

Innovative drying technology system The world's first multi-dimensional dynamic drying device integrates the revolution/rotation composite motion mode and the gradient temperature control system, and cooperates with the bottom blowing/side blowing directional wind field technology to overcome the industry problem of the difference in drying on the leeward side of the shell, and improves the drying efficiency by 40% while reducing the crack rate to below 0.3%.

Internet of Things traceability management system

Internet of Things traceability management system RFID intelligent identification technology is applied, and anti-interference radio frequency tags are used to achieve product traceability throughout the life cycle. Compared with the traditional barcode system, the recognition accuracy rate is increased to 99.99%, providing a reliable data foundation for flexible manufacturing.